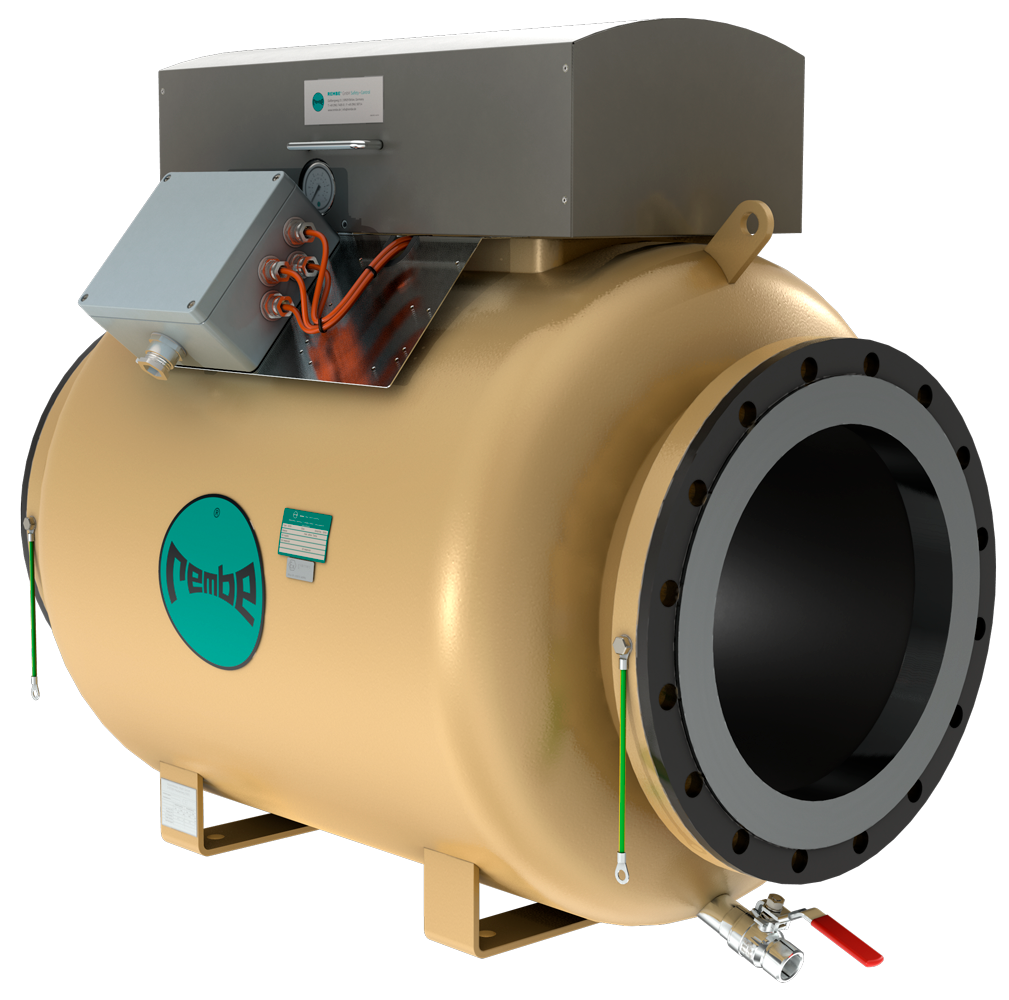

EXKOP® QV III

Space-saving, bidirectional isolation.

Decoupling with quench valves.

The REMBE® EXKOP® QV III quench valve is a decoupling device that is installed in a pipeline in order to limit any explosions to the relevant part of the system. To do this, the quench valve is connected to a controller (EXKOP® Express or EXKOP® TriCon).

Application

REMBE® EXKOP® QV III is suited with a Spark arrester (e.g. between a mill and the product filter) and an overpressure limiter (e.g. between a silo vehicle and the silo).

Advantages

-

Compact design for flexible integration into the production process.

-

High level of safety due to very rapid closing times.

-

Returns to operation immediately after triggering.

-

Fail Safe mechanism automatically closes the valve if the power supply fails or the valve is manipulated.

Mechanism

In the case of an explosion, the controller receives a trigger signal (e.g. from the signalling unit of the Q-Rohr® or an explosion vent, from a pressure switch or spark detector) and activates the connected quench valves. These close within a few milliseconds and thus prevent the explosion from spreading to adjacent plant components. After being triggered, the quench valves can be put back in operation once again at the touch of a button.

Technical data *

Product parameters

| Diameter nominal** | DN 300 - DN 600 |

|---|---|

Housing material | St 37.2, painted (RAL 1015) |

Flanges | acc. EN 1092-1 Typ 11 (PN 10)*** |

Operating limits Medium | organic and chemical dusts |

Operating limits KSt | ≤ 200 bar × m/s |

Operating limits Pmax | ≤ 10 bar |

Operating limits MZE | ≥ 3 mj |

Operating limits Pred | ≤ 1,0 bar |

Operating limits Allowable flow rate | ≤ 30 m/s |

Operating limits ATEX category indoor/outdoor | 1D/3D |

Suitable for use in food processing industry | ✓ |

Ambient temperature | + 5 up to + 60 °C**** |

Installation position | any |

Power supply | 24 VDC from EXKOP® controller |

Compressed air supply | 6.0 bar gauge pressure from system network |

Compressed air connection | 8 mm (Festo) |

Protection type | IP 65 |

* Our specialists will be pleased to assist you in finding a solution that matches your specific operating conditions.

** Other nominal diameters available on request.

*** Replaces DIN 2632, PN 10.

**** Other ambient temperature available on request.

** Other nominal diameters available on request.

*** Replaces DIN 2632, PN 10.

**** Other ambient temperature available on request.

Applications + Industries

-

animal feed productions

-

aspiration plants

-

brewery

-

conveyors

-

destoners

-

elevators

-

filters

-

food

-

food production

-

mills and grinding plants

-

mixers

-

recycling

-

screens

-

silo

-

spray dryers

-

wood processing

Certifications

ATEX EC type

examination certificate no.

FSA 15 ATEX 1659 X

Certified in

accordance with

EN 15089

The EXKOP® system is ideal in combination with explosion vents or flameless explosion venting solutions.

REMBE® EXKOP® QV III

at the production.

REMBE® EXKOP® QV III

at the production.

REMBE® EXKOP® QV III

at the production.

Click and drag image to view.

The dimensions shown may differ from those of the actual product.

* Requires iOS 13, iPadOS 13, ARCore 1.9 or higher.

* Requires iOS 13, iPadOS 13, ARCore 1.9 or higher.

Unboxed - EXKOP® Maintenance

Your contact person

I will be happy to advise you about the most suitable Protection systems for your plant. Individually, in detail and taking all relevant parameters into account.

Andre Häger | Sales Executive Explosion Safety